Supply Chain Planning Preparation & Performance Management

Overview of the training: In today’s globally competitive environment; organizations survive by leveraging their often complex supply chains to provide value to customers. Organizations must be able to provide the right goods and services to the right customers, in the right quantity, in the right place and time, and at the right costs. Failure to do so could have a significant negative impact on the bottom line. This course is designed and articulated to sharpen participants knowledge and skills in doing /operating supply chain efficiently and successfully. Learning the process and procedure of supply chain basics, tools, techniques, challenges/ risk …

Curriculum

Overview

Overview of the training:

In today’s globally competitive environment; organizations survive by leveraging their often complex supply chains to provide value to customers. Organizations must be able to provide the right goods and services to the right customers, in the right quantity, in the right place and time, and at the right costs. Failure to do so could have a significant negative impact on the bottom line.

This course is designed and articulated to sharpen participants knowledge and skills in doing /operating supply chain efficiently and successfully. Learning the process and procedure of supply chain basics, tools, techniques, challenges/ risk factors and solutions and success issues, conducting research, and staying informed can help you succeed in your supply chain operation. Real-life processes and procedures have been described in this training program, as participants can gather knowledge easily and implement the training result in real-life operations/businesses. This course is planned in such a way that within a short period of time the participants can engage them in operating the supply chain in real life. Participants will be truly benefited and confident just walk away from the training room.

Supply Chain Management (SCM) is the design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand, and measuring performance locally and globally.

Supply chain management deals with inputs, conversion, and outputs. A supply chain consists of three types of entities: customers, a producer, and the producer’s suppliers. Supply chain management oversees and optimizes the processes of acquiring inputs from suppliers (purchasing), converting those inputs into a finished product (production), and delivering those products – or outputs – to customers (fulfillment).

Supply chain managers decide where to locate manufacturing and distribution facilities, how to route goods and materials among those facilities, and from which parts of the world to source the inputs.

Who should attend?

The professionals engaged in Supply Chain, Export, Import, Procurement, Logistics, Distribution, Production, Finance, HR, R&D, Engineering, Shipping, Freight Forwarding, Customs, Courier, Supply, Sales& Marketing, Specially Fresher, Post Graduate Business Students, SCM Training and more those are involved in Private Sector, Public sector, and Nonprofit organizations (NGOs)

Objectives of this training:

- Explain the basic concept of SCM and LM

- It aims to provide participants foundational and advanced knowledge on how to tackle, resolve, and manage myriad complex problems and issues that confront supply chain managers.

- The purpose of the course is to recognize the interrelationship of supply chain functions and to understand how all parts of the supply chain work.

- Professional involves in Supply Chain Management(SCM) as they can minimize cost

- Supply the products and services to the right places at the right time and satisfy the customer

Learning Methodology:

- Lecture & discussion

- Powerpoint Presentation

- Peer learning

- Group work and presentation

- Experience

- Roleplay

- Buzz and simulation games

- Case study exercises

- Video clip

Training Contents:

Supply chain planning

- What is Supply Chain Planning

- Demand Planning

- Supply Planning

- Fund Requirement Planning

- Planning as Supply Target (Quality,

- Cost, Time, Availability, Suppliers Services)

- Planning as per Supply Chain Functions

- Planning as per Supply Chain Mix=8P+3R+3R =Supply Chain Success

- Types of Forecasting Methods

- Methods of Forecasting Demand

- Bullwhip Effect

- MRP, MRP II

- ERP

- DRP

- SCM CASES, EXERCISES, VIDEO, GAMES, ROLE PLAY

Supply Market, Supplication, Wives, Relationships, Motivation, Culture & Cost Analysis in Supply Chain Management:

- Supply Market Analysis

- Use the Supply Chain Models to Analyse

- Qualitative Analysis and Quantitative Analysis

- Supplier and Supplier Country Analysis

- Buyer and Buyer Country Analysis

- Relationship Analysis

- Supplier offer Analysis

- Organizational Environment and Culture Analysis

- Culture Analysis

- Motivation Analysis

- Supply Chain Cost Analysis

- Life Cycle Cost/ TCO Analysis

- Pre-transactions, Transactions and Post Transactions Cost in Supply Chain

- Learning Check

- SCM CASES, EXERCISES, VIDEO, GAMES, ROLE PLAY

Supply Chain Performance Management:

- Meaning of Performance Management

- Performance Measurement Methods(Qualitative and Quantitative methods )

- Supply Chain Activity wise Performance Management

- Supply Target-wise Performance Measurement

- Supply availability performance

- Lead-time & delivery performance

- Quality Performance

- Customer service performance

- Cost performance

- Managing time, quality, and cost (Corrective actions 🙂

- Efficiency measurement in purchasing and supply:

- Learning Check

- SCM CASES, EXERCISES, VIDEO, GAMES, ROLE PLAY

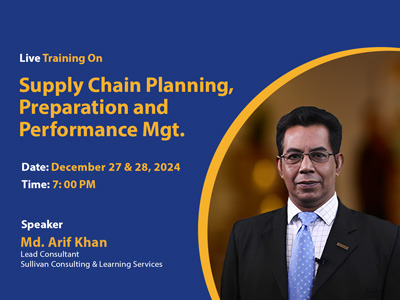

Training Instructor:

Courses of this Instructor: